×

×

Take your jewelry production to the next level with our advanced laser welding machines that guarantee precision, strength, and an impeccable finish for your exquisite creations.

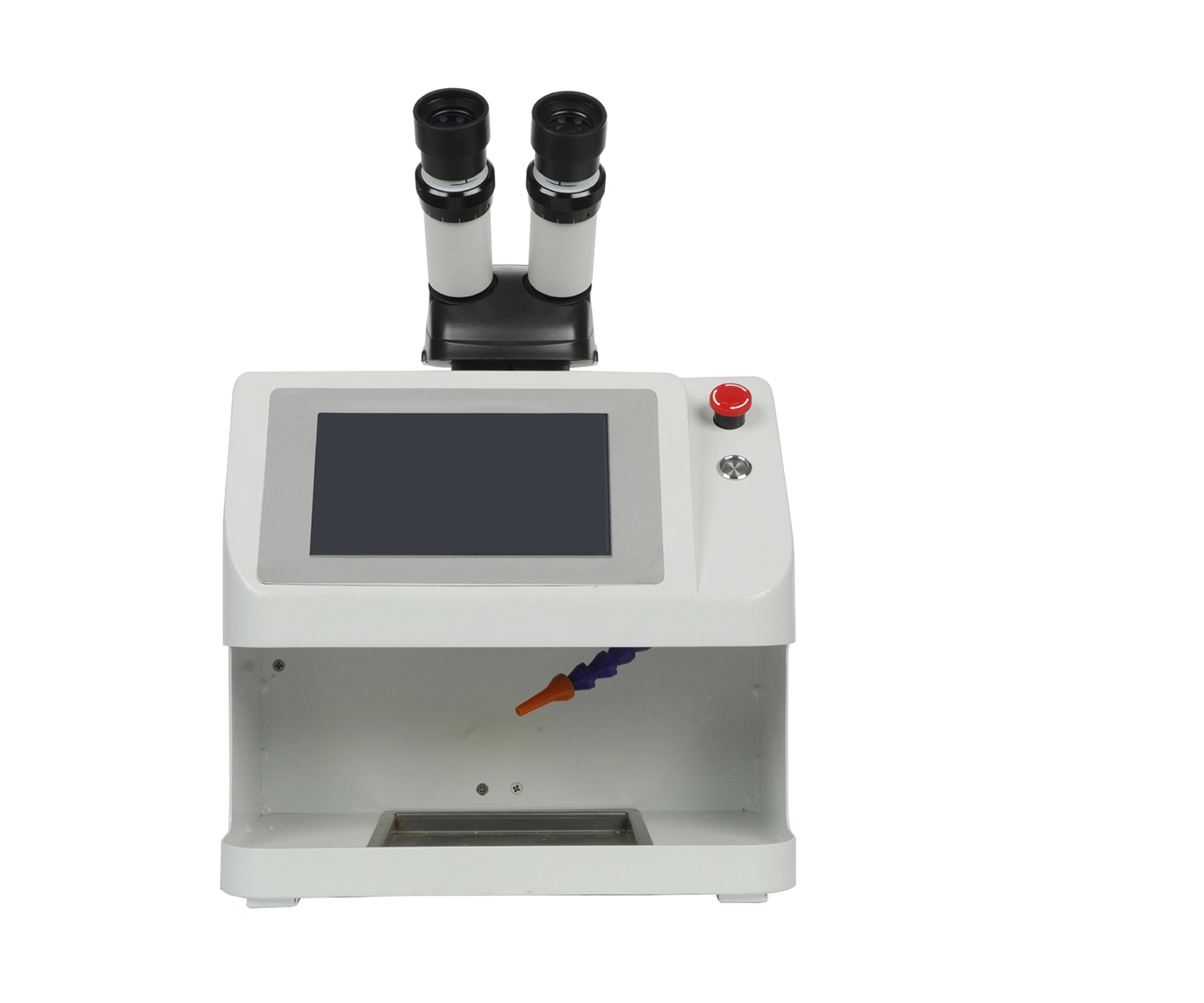

The Magic Cube Laser Laser Jewelry Welding Machine – the ultimate solution for precision jewelry welding needs. Engineered with cutting-edge technology, this machine offers unparalleled performance and efficiency in a wide range of applications.

Fully Automatic Operation: Our Laser Jewelry Welding Machine is designed for seamless integration into your production line. With its intuitive user interface and advanced automation features, it ensures consistent and accurate results every time.

Built-in Water Cooling System: To maintain optimal performance and longevity, the machine is equipped with an advanced water cooling system. This feature ensures that the laser remains at a stable temperature, even during extended use.

Precision Engineering: The Laser Jewelry Welding Machine delivers exceptional precision with its high-resolution capabilities. Whether you need to weld intricate designs or detailed jewelry pieces, this machine delivers sharp and clear results every time.

Versatility: With its ability to work with a variety of materials, including precious metals, gemstones, and more, the Laser Jewelry Welding Machine is an ideal choice for a diverse range of industries, including jewelry manufacturing, repair, and restoration.

In summary, the Magic Cube Laser Laser Jewelry Welding Machine is an investment in quality, precision, and efficiency. Whether you're looking to enhance your production capabilities or improve the quality of your finished products, this machine is the perfect solution.

Magic Cube Laser Jewelry Welding Machines lead the way in sustainable manufacturing practices.By minimizing material waste and energy consumption, these machines epitomize environmental responsibility without sacrificing performance. Embrace green technology that aligns with ecological standards and produces exceptional welding outcomes.

Our commitment to sustainability extends beyond mere production; it touches every aspect of our operations. Magic Cube Laser Jewelry Welding Machines are designed with longevity in mind, reducing the need for frequent replacements and promoting a circular economy. Be part of the solution, not the problem, with equipment that values both quality and our planet.

At Magic Cube Laser, we understand that eco-conscious choices are paramount. That's why our machines are optimized for efficiency, using the latest technology to lower their carbon footprint. Experience responsible manufacturing that delivers on aesthetics and ethics, ensuring that your craft is as kind to the environment as it is to the eye.

Industries such as medical and manufacturing demand nothing less than perfect precision. Magic Cube Laser Jewelry Welding Machines rise to this challenge, providing exacting standards of precision crucial for parts marking, instrument customization, and component traceability. Trust in our machines to deliver when accuracy is non-negotiable.

Maintain compliance with regulatory requirements through clear and permanent markings achieved by Magic Cube Laser Jewelry Welding Machines. Ideal for serial numbering, production dating, and logo branding, these machines ensure that important information is always legible and long-lasting, simplifying inventory management and quality control processes.

Specialized industries have unique needs, and Magic Cube Laser Jewelry Welding Machines are designed to cater to these specifications. Whether you require small-scale precision or large-format marking capabilities, our machines are configurable to meet tight tolerances and exacting standards.Choose reliability and accuracy for your critical applications.

The Laser jewelry welding machine of Magic Cube Laser is becoming an important driving force for the upgrading of the jewelry industry. Its core technology solves the problem of refinement difficult to deal with by traditional welding methods, and brings new possibilities for high-end jewelry customization and mass production.

With the help of high speed and accurate Laser beam, the welding function of the Magic Cube Laser is precisely applied to a very small area, which is especially suitable for the welding of small gaps, thin chains and gemstone setting and other complex parts, greatly improving the detailed expression and overall quality of jewelry products.

Through real-time monitoring and closed-loop feedback system, the welding machine can achieve precise control of welding parameters, whether it is soft gold, hard silver or alloys with different melting points, it can complete high-quality welding under the most suitable conditions. Not only that, the supporting training support and after-sales service also help enterprises quickly master the operation skills of new equipment.

In general, the Laser jewelry welding machine of Magic Cube Laser not only provides strong technical support, but also helps enterprises to break through the traditional processing bottleneck, accelerate to the direction of intelligence and precision, so as to occupy a favorable competitive position in the global jewelry market.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our laser jewelry welding machine can weld gold, silver, platinum, and other precious metals.

Our laser jewelry welding machines utilize advanced fiber or YAG laser technology, suitable for precise and clean welding in the jewelry industry.

The power output ranges from 50W to 300W, which can be adjusted according to the intricacy and material of the jewelry pieces.

Yes, we offer customization services to meet the specific needs of our customers.

Yes, the machine has multiple welding modes including pulse, continuous, and quasi-continuous mode, enabling users to tailor the process to delicate jewelry components.

Our laser welding machines consume energy efficiently, especially compared to traditional methods, and many have energy-saving modes for reduced operational costs.