×

×

Discover the power of precision laser welding technology to craft stunning jewelry pieces with fine detailing and exceptional strength, meticulously fused together.

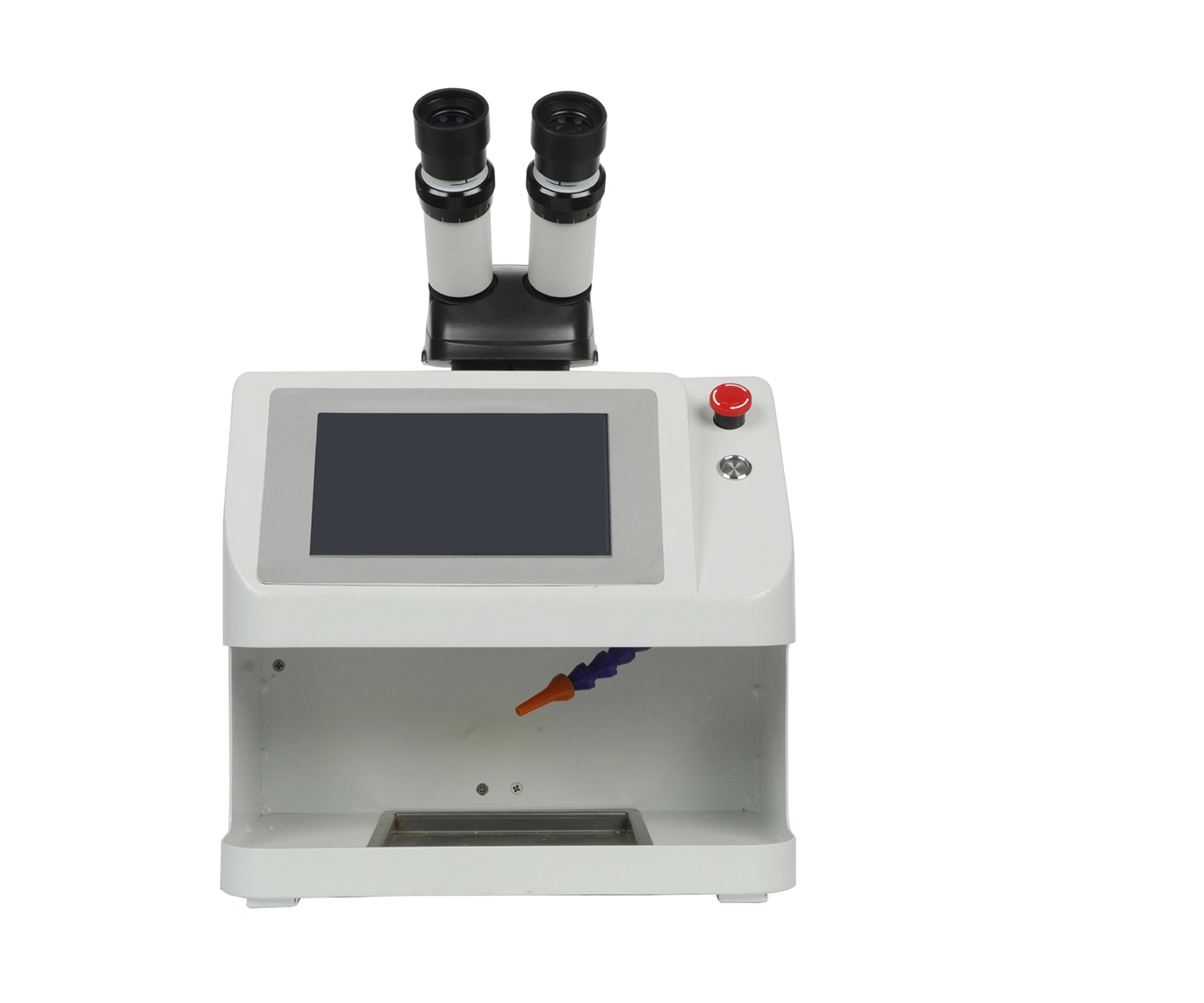

In these days, laser jewelry welding machine made by Magic Cube Laser is a technological revolution in modern jewelry production industry. It goes beyond the constraints of manual traditional welding and makes non-destructive and zero-error welding using accuracy controlled laser technology.

The welder combines superior laser light source technology with smart operating system to enable one click automatic welding of even complex configurations of metals, thus increasing labour productivity. Furthermore, the cooling mechanism used in this device prevents overheating from destroying delicate jewelry material resulting in excellent aesthetic appeal.

Magic Cube Laser’s laser jewelry welders are designed to ensure that they work safely with all kinds of precious metal or alloy including those with gems. Jewellery designers can now be innovative since they are no longer bound by old-fashioned methods of joining pieces together.

For any company willing to invest on Magic Cube Laser’s machines for laser-jewelry-welding purposes, will improve its products reliability as well as their designs flexibility thus giving them an upper hand against other rivals especially regarding competition in market places. This tool is not only a crucial component for enhancing the manufacturing process but also facilitates technological change within the gem business.

The jewelry industry is driven by Magic Cube Laser’s laser jewelry welding machine. Through its core technology, traditional welding methods that were difficult to handle in the past have found solace in it as well as offering new opportunities for mass production and customization of valuable jewelry.

The Magic Cube Laser uses a high speed and precision laser beam to weld very small areas. It is suitable for welding small gaps, thin chains, gemstone setting and other complex parts which are usually found in jewelry manufacture. This greatly improves the details and overall quality of the same.

Welding parameters can be precisely controlled by the welding machines through real-time monitoring and closed-loop feedback system. Under ideal conditions, whether soft gold, hard silver or different melting point alloys are used, it can accomplish perfect welding. In addition to this, supportive training programs along with after sale services help firms quickly learn how to operate new equipment.

Generally, not only does the Laser Jewelry Welding Machine from Magic Cube Laser provide technical support but also helps enterprises overcome traditional processing bottlenecks so as to accelerate towards smartness and accuracy in order to gain favorable competitive positions in the global market of jewels.

Industries like medical and manufacturing industries are very precise in nature. Magic Cube Laser Jewelry Welding Machines meet this standard by providing a critical level of precision needed for parts marking, instrument customization, and component traceability. Depend on our machines when accuracy is a must.

Magic Cube Laser Jewelry Welding Machines help to achieve clear and permanent markings that maintain compliance with regulatory requirements. They are perfect for serial numbering, production dating, and logo branding ensuring that important details are visible all the time thereby making inventory management and quality control processes easy.

Specialized industries have unique needs which can be met by Magic Cube Laser Jewelry Welding Machines. When it comes to small-scale precision or large-format marking capabilities, our machines can be configured so as to comply with close tolerances as well as exact standards.Select reliability and precision for your mission-critical applications.

When it comes to sustainability, Magic Cube Laser Jewelry Welding Machines are in the lead.

These machines are an embodiment of environmental responsibility while still maintaining their performance as they minimize material wastage and energy consumption. Opt for ecological-friendly green technology that gives you excellent welding outputs.

Our commitment to sustainability is not just restricted to production, but extends to all aspects of our operations. Magic Cube Laser Jewelry Welding Machines also aim at reducing regular replacements due to their long-lasting design and therefore promoting circular economy. Have a part in the solution and not the problem with machines that appreciate quality as well as our earth.

At Magic Cube Laser, we are aware that eco-conscious choices matter most. This is why our machines have been designed to be efficient, making use of up-to-date technology in order to cut down on carbon emissions. Have a taste of responsible manufacturing from each angle-looks and ethics which will make sure your craft is friendly both in terms of environment as well as the eyes.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our laser jewelry welding machine can weld gold, silver, platinum, and other precious metals.

Our laser jewelry welding machines utilize advanced fiber or YAG laser technology, suitable for precise and clean welding in the jewelry industry.

The power output ranges from 50W to 300W, which can be adjusted according to the intricacy and material of the jewelry pieces.

Yes, we offer customization services to meet the specific needs of our customers.

Yes, the machine has multiple welding modes including pulse, continuous, and quasi-continuous mode, enabling users to tailor the process to delicate jewelry components.

Our laser welding machines consume energy efficiently, especially compared to traditional methods, and many have energy-saving modes for reduced operational costs.