×

×

Boost product identification and traceability with our advanced PCB laser marking technology, ensuring clear and lasting marks.

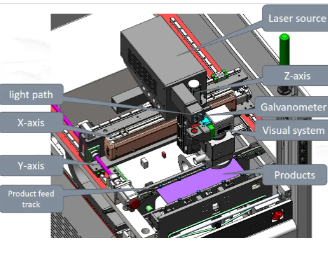

With its precision and efficiency, Magic Cube Laser’s PCB marking machines transform the marking process in the electronics manufacturing sector. This machine uses advanced laser technology to perform fine markings at the micrometer level on a range of types of circuit boards (PCBs) such as component location identification, 2D bar-code and serial number information.

This PCB marking machine is designed specifically for the needs of the electronics industry and can easily handle different materials and dimensions of circuit boards, ensuring durable and clear mark information during high temperature welding as well as complex production environments, meeting strict requirements for quality traceability.

Intelligent control system enables automatic positioning function that can accurately position even with high density wiring on PCBs resulting in significant improvement in throughput of production lines. Moreover, it has compact design and modular structure for easy installation or maintenance hence making it adaptable to different production environments.

When you choose a Magic Cube Laser PCB marking machine, your business merges intelligent manufacturing processes that lower operating expenses while enhancing product traceability and quality assurance hence strengthening competitive advantage within electronics market.

A PCB marking machine carefully built by Magic Cube Laser used laser technology as an eco-friendly alternative to the conventional printing or etching methods, resulting in non-contact and zero pollution permanent circuit board engraving. It not only enhances work efficiency but responds positively to a demand for industrial green development.

This PCB marking machine has remarkable precision and stability that can perform complicated graphic and text markings within a small area, which is perfectly in line with the tendency of electronic devices component miniaturization. By optimizing energy consumption it effectively reduces its carbon footprint as stipulated in sustainable development strategies.

Equipped with visual identification system that uses advanced technologies, the equipment automatically recognizes and corrects itself for the required marking space on the PCB thereby minimizing human intervention during assembly hence efficient integrated assembly lines. Additionally, this software is strong enough to support data uploading using multiple files allowing clients freedom to customize their labeling contents flexibly.

The investment made by companies in purchasing Magic Cube Laser’s PCB marking machines will enable them quickly advance into new era characterized by ecological cleanliness and intelligent manufacturing thus giving a higher grade product mark and enhancing brand competitiveness.

The introduction of a new generation of PCB marking machines by Magic Cube Laser, which integrate high-speed dynamic focusing, 3D marking and so on, enables diversified and personalized marking on increasingly complex boards.

These sets of machines for PCB marking boast excellent depth control abilities that enable uniform and delicate marking effect both on one-sided or two-sided as well as multi-layer circuit boards; it can also allow accurate identification and providing marks for extra small-size components.

Advanced machine vision and AI algorithms have been incorporated into the equipment to enable dynamic alteration of the marking scheme given the actual layout of the PCB thereby improving flexibility and adaptability in mass production. This is complemented by an intuitive interface that facilitates easy interaction with users so as to streamline their work flow.

Therefore, this series of technological inventions that has come up through Magic Cube Lasers’ PCB Marking Machines has set another milestone in electronics manufacturing sector while boosting productivity and boosting product quality among firms in readiness to address the increased demands from companies.

Magic Cube Laser is dedicated to offering advanced PCB marking solutions, and its new standard of quality in electronic manufacturing has been achieved through the use of high performance laser marking equipment. Using intense laser beam, it can form moderate depth and wear resistant imprints on PCB surface.

This PCB marking device has a highly integrated structural design as well as strong compatibility that meets the requirements of various circuit boards like multi-layer board and flex board. Simultaneously, this prevents sensitive electronic elements from overheating by carefully controlling laser energy.

Additionally, Magic Cube Laser’s PCB marking machine also incorporates real-time quality validation mechanism to ascertain completeness and correctness of each mark; thus reducing cases of product recalls that might result from wrong marks.

In conclusion, the great thing about choosing Magic Cube Laser’s PCB marker is that companies will enhance their products’ traceability and anti-counterfeiting functionality but most importantly improve overall production efficiency hence ensuring their market position becomes stronger for a more refined, standardized modern electronics manufacturing path.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our PCB marking machines have an accuracy of ±0.01mm, ensuring high-quality and precise markings.

The power consumption varies depending on the model and usage. However, our machines are designed to be energy-efficient, reducing operating costs for our clients.

We adhere to strict quality control standards throughout the manufacturing process, and all machines undergo rigorous testing before shipment to ensure they meet our high-quality standards.

Our PCB marking machines utilize advanced laser technology, inkjet printing, or dot peen marking depending on the level of permanence and detail required.

Our PCB marking machines are highly energy-efficient, consuming less power than traditional marking methods, and often include power-saving modes.

Yes, our laser marking method ensures minimal heat exposure and no mechanical stress, safeguarding sensitive components on the PCB during the marking process.