×

×

Design your jewelry with the finest details using our premium laser welding machines, ideal for enthusiasts and professionals alike, promising elegance in every joint.

The jewelry industry is driven by Magic Cube Laser’s laser jewelry welding machine. Through its core technology, traditional welding methods that were difficult to handle in the past have found solace in it as well as offering new opportunities for mass production and customization of valuable jewelry.

The Magic Cube Laser uses a high speed and precision laser beam to weld very small areas. It is suitable for welding small gaps, thin chains, gemstone setting and other complex parts which are usually found in jewelry manufacture. This greatly improves the details and overall quality of the same.

Welding parameters can be precisely controlled by the welding machines through real-time monitoring and closed-loop feedback system. Under ideal conditions, whether soft gold, hard silver or different melting point alloys are used, it can accomplish perfect welding. In addition to this, supportive training programs along with after sale services help firms quickly learn how to operate new equipment.

Generally, not only does the Laser Jewelry Welding Machine from Magic Cube Laser provide technical support but also helps enterprises overcome traditional processing bottlenecks so as to accelerate towards smartness and accuracy in order to gain favorable competitive positions in the global market of jewels.

The manufacturing of jewelry today has been changed by Magic Cube Laser’s Laser Jewelry Welding Machine and this has become the new standard in terms of quality, precision and speed. The machine uses a high energy laser beam that is focused very tightly to produce an output that can weld metal at the micron level, thus ensuring strong and seamless connections among various jewelry components made of precious metals such as gold, silver or platinum.

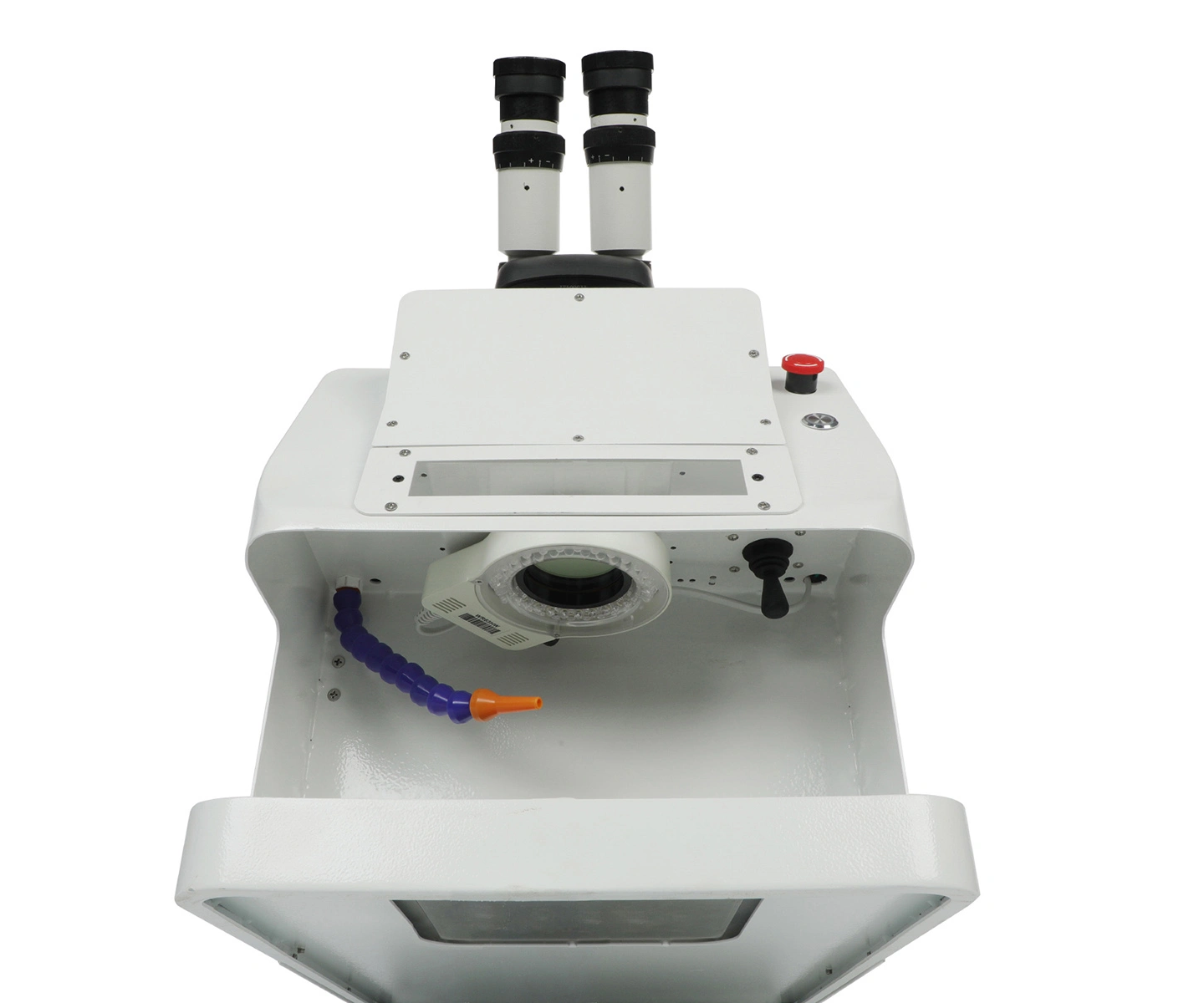

With a fully automated control system installed on a magic cube laser’s jewelry welding machine, it requires little effort to master but is highly reliable even when it comes to repairing small linkages or creating elaborate mosaics. It boasts an inbuilt cooling system for water that ensures the temperatures within the unit remain constant throughout its long duration of operation; thereby, safeguards expensive jewels from being damaged by heat while at the same time prolonging its life span.

Its unique selling proposition lies in its capability to manipulate various delicate parts particularly for fine repairs and innovative designs within the jewellery sector. With ultra-low input heat and accurate positioning methods, users are able to carry out high-quality welding without causing harm to gems or any other delicate part.

Magic Cube Laser’s Laser Jewelry Welding Machine combines modern design ideas with cutting edge technologies resulting into improved production rates and unmatched texture refinement as well as durability for jewelry pieces. This innovative solution is without question priceless for jewelers searching for exceptional quality.

Industries like medical and manufacturing industries are very precise in nature. Magic Cube Laser Jewelry Welding Machines meet this standard by providing a critical level of precision needed for parts marking, instrument customization, and component traceability. Depend on our machines when accuracy is a must.

Magic Cube Laser Jewelry Welding Machines help to achieve clear and permanent markings that maintain compliance with regulatory requirements. They are perfect for serial numbering, production dating, and logo branding ensuring that important details are visible all the time thereby making inventory management and quality control processes easy.

Specialized industries have unique needs which can be met by Magic Cube Laser Jewelry Welding Machines. When it comes to small-scale precision or large-format marking capabilities, our machines can be configured so as to comply with close tolerances as well as exact standards.Select reliability and precision for your mission-critical applications.

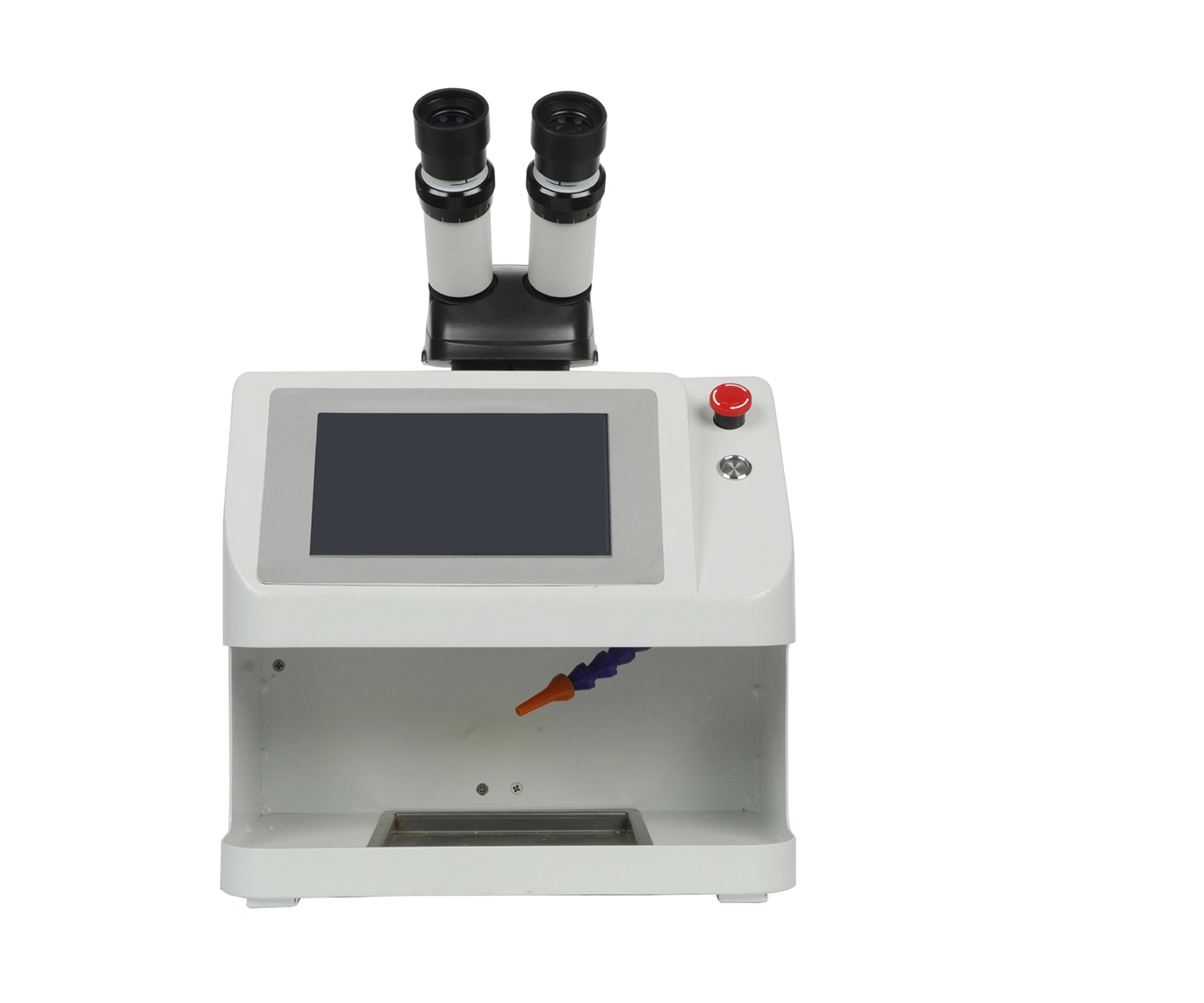

The ideal solution for the intricate jewelry welding needs is the Magic Cube Laser Laser Jewelry Welding Machine.

This machine has been engineered using cutting-edge technology and it offers unmatched performance and efficiency across various applications.

Fully Automated Operation – Seamlessly integrate our Laser Jewelry welding machine into your production line. This ensures continuous, accurate results through its friendly user interface and sophisticated automation capabilities.

Internal Water Cooling System: For optimal performance and long life of this machine; an advanced water cooling system is incorporated in it. This feature guarantees that the laser remains at a consistent temperature even during extended periods of use.

Precise Engineering- The Laser Jewelry Welding Machine comes with high resolution abilities that ensures you get an incredible precision. Whether you need to solder complex patterns or detailed pieces of jewelry, this device will produce sharpness every time.

All Round Equipment: The Laser Jewelry Welding Machine can work on many materials such as precious metals, gemstones among others hence making it suitable for various industries like jewelry manufacturing, repair and restoration processes.

In summary, when one invests in the Magic Cube Laser Laser Jewelry Welding Machine he or she chooses quality, accuracy as well as productivity. Whether a person wants to boost production capacities or enhance quality of finished products, this tool is just perfect to do so.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our laser jewelry welding machine can weld gold, silver, platinum, and other precious metals.

Our laser jewelry welding machines utilize advanced fiber or YAG laser technology, suitable for precise and clean welding in the jewelry industry.

The power output ranges from 50W to 300W, which can be adjusted according to the intricacy and material of the jewelry pieces.

Yes, we offer customization services to meet the specific needs of our customers.

Yes, the machine has multiple welding modes including pulse, continuous, and quasi-continuous mode, enabling users to tailor the process to delicate jewelry components.

Our laser welding machines consume energy efficiently, especially compared to traditional methods, and many have energy-saving modes for reduced operational costs.