×

×

Deter counterfeiters and protect your brand with our advanced PCB marking machine, providing permanent and clear product identification.

Magic Cube Laser is committed to providing cutting-edge PCB marking solutions, and its high-performance laser marking equipment has brought a new standard of quality to electronics manufacturers. Using a high-intensity laser beam, a moderate depth and wear-resistant imprint can be formed on the PCB surface.

This PCB marking device has a highly integrated structural design and strong compatibility, which is suitable for the marking needs of various types of circuit boards such as multi-layer boards and flexible circuit boards. At the same time, by precisely controlling the laser energy, the effect of overheating on sensitive electronic components is effectively prevented.

In addition, the PCB marking machine of the Magic Cube Laser also introduces a real-time quality inspection mechanism to ensure the integrity and accuracy of each marking, which greatly reduces the risk of product recall due to mismarking.

In summary, enterprises that choose Magic Cube Laser PCB marking equipment will improve product traceability and anti-counterfeiting capabilities at the same time, but also effectively improve the overall production efficiency, and then consolidate the market position, towards a refined, standardized modern electronic manufacturing road.

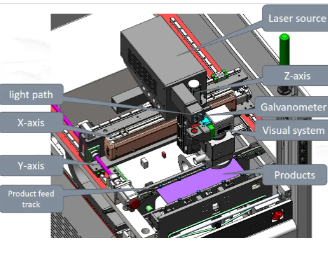

PCB marking machines from Magic Cube Laser revolutionize the marking process in the electronics manufacturing industry with their precision and efficiency. The device uses advanced laser technology to achieve fine marking at the micron level on various types of circuit boards (PCBS), including but not limited to component location identification, two-dimensional code and serial number information.

This PCB marking machine is customized for the special needs of the electronics industry, and can easily cope with various materials and sizes of circuit boards, ensuring that the marking information is durable and clear in high temperature welding and complex production environments, and meet the strict quality traceability requirements.

Its intelligent control system integrates automated positioning functions, enabling precise alignment even in the face of high-density PCB wiring, significantly improving production line efficiency. At the same time, the compact design and modular construction make the equipment easy to install and maintain, and adapt to different production environments.

The choice of Magic Cube Laser PCB marking machine means that enterprises can seamlessly connect intelligent manufacturing processes, reduce operating costs, but also improve product traceability and quality assurance, thus helping enterprises to occupy an advantageous position in the highly competitive electronics industry.

Magic Cube Laser continues to lead PCB marking technology innovation, introducing a new generation of PCB marking machines that integrate high-speed dynamic focusing, three-dimensional marking and other functions, making it possible to achieve diversified and personalized marking on increasingly complex circuit boards.

This series of PCB marking machines have excellent depth control capabilities, whether it is on single - and two-sided or multi-layer circuit boards can achieve uniform, fine marking effect, even ultrafine components can be accurately identified and marked.

The device integrates advanced machine vision and AI algorithms to intelligently adjust the marking scheme according to the actual PCB layout, greatly improving the flexibility and adaptability of mass production. Not only that, but the intuitive and user-friendly interface further simplifies the operator's workflow.

In short, Magic Cube Laser's PCB marking machines set a new benchmark in the electronics manufacturing industry with a series of technological innovations, bringing higher productivity and product quality to companies and fully preparing for more demanding industry challenges.

The carefully built PCB marking machine by Magic Cube Laser uses environmentally friendly laser technology to replace traditional etching or printing methods, and completes the permanent marking of the circuit board in a non-contact and zero-pollution way. It not only improves work efficiency, but also actively responds to the call of industrial green development.

This PCB marking machine has excellent accuracy and stability, and can carry out complex graphic and text marking in a small space, which perfectly fits the development trend of miniaturization of electronic components. By optimizing energy consumption, it effectively reduces its carbon footprint in line with sustainable development strategies.

The equipment is equipped with an advanced visual identification system that automatically captures and calibrates the marking area on the PCB, greatly reducing manual intervention and achieving efficient and accurate integrated assembly line operation. Moreover, powerful software supports data import in multiple formats, allowing customers to customize markup content flexibly.

By investing in the PCB marking machine of Magic Cube Laser, enterprises will be able to quickly upgrade to a new stage of green environmental protection and intelligent production, giving products a higher quality mark, and enhancing the competitiveness of the brand in the industry.

Magic Cube Laser Technology (Shenzhen) Co., Ltd. is a company specializing in the research, development, production and sales of laser equipment. Our product range includes laser marking machines, jewelry welding machines, welding machines and cutting machines, etc. We are committed to providing customers with high-quality, high-efficiency laser equipment solutions.

Our laser marking machines use high energy density laser beams for marking, which can quickly and accurately print marks and patterns on a variety of materials. Jewelry welding machines can complete the welding of metal jewelry in an efficient and precise manner. Welding machines and cutting machines can be widely used in welding and cutting processes of various metallic and non-metallic materials.

Optimized design and high-performance components enable fast and efficient operation.

We constantly introduce new products and use the most advanced technology to provide innovative products.

Our equipment is versatile and fully functional to meet the various needs of different industries.

We focus on customer needs and provide personalized customization and high-quality after-sales service

Our PCB marking machines have an accuracy of ±0.01mm, ensuring high-quality and precise markings.

The power consumption varies depending on the model and usage. However, our machines are designed to be energy-efficient, reducing operating costs for our clients.

We adhere to strict quality control standards throughout the manufacturing process, and all machines undergo rigorous testing before shipment to ensure they meet our high-quality standards.

Our PCB marking machines utilize advanced laser technology, inkjet printing, or dot peen marking depending on the level of permanence and detail required.

Our PCB marking machines are highly energy-efficient, consuming less power than traditional marking methods, and often include power-saving modes.

Yes, our laser marking method ensures minimal heat exposure and no mechanical stress, safeguarding sensitive components on the PCB during the marking process.