×

×

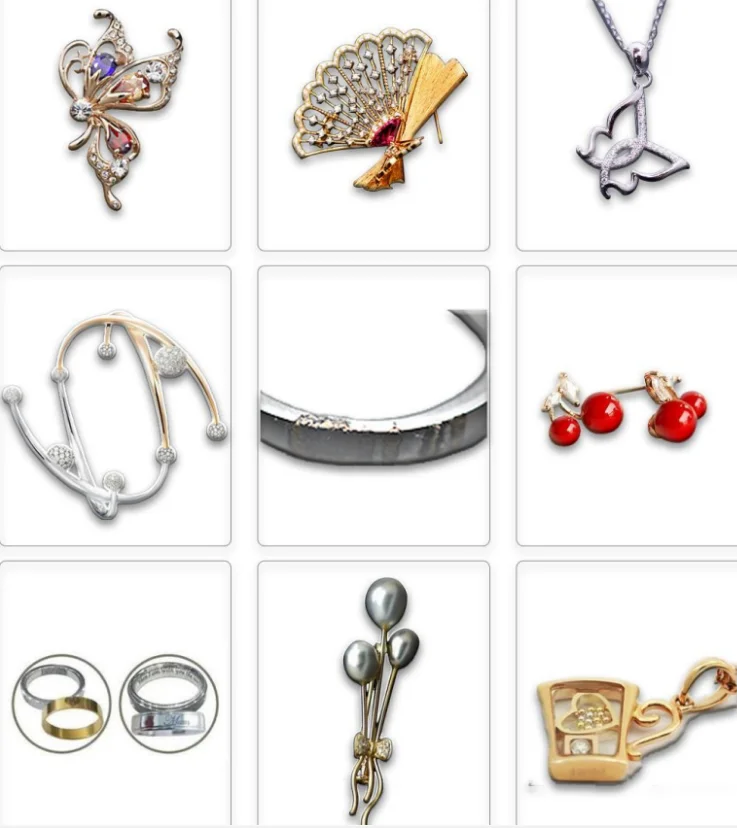

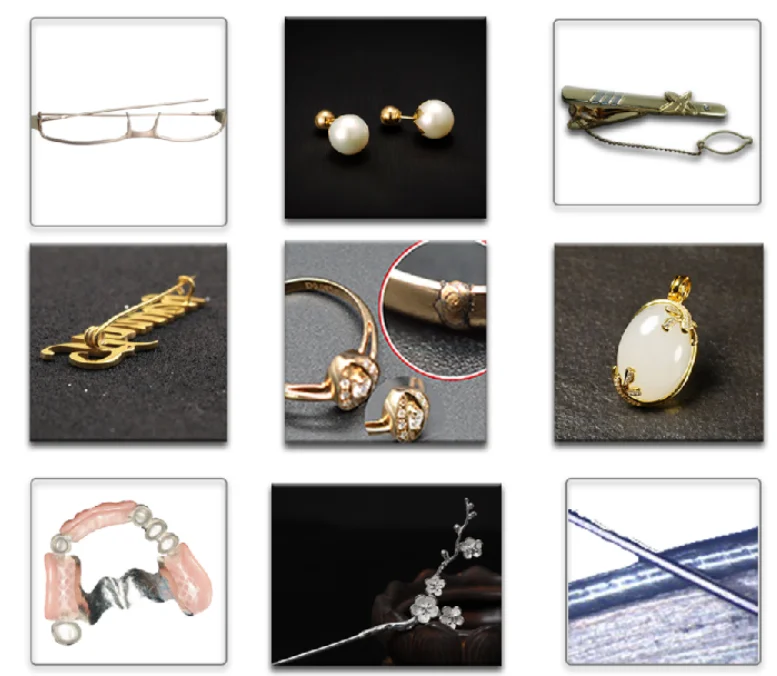

Aplication industries:

|

1.High-definition microscope Precise welding of fine small products,built-in protective grating, long-term welding without hurting the eyes |

|

2.Color high-definition touch display screen adjust current, pulse width, light spot, etc., high-definition CCD display visual inspection system, welding points are clearly visible |

|

|

3.Emergency stop button emergency switch One-button switch, simplifying the device startup process, easy and safe to operate |

| 4.The vertical and inverted design of the control screen is convenient for installation and transportation |

|

|

5.3D soft bag elbow tray humanized design, long-term work without fatigue |

|

1.3600 ring-shaped shadowless cold light 2.Joystick 3.Air valve 4.Material collection tray 5.The workbench has a large internal space and convenient to use. It is equipped with material collection tray, an air valve and Joystick, and is equipped with a 3600 ring-shaped shadowless cold light |

|

|

|

The first modular independent function design in China, the use method is simpler and more convenient, making it more convenient for customers to use Independent unit module design of each functional component, easy to install, produce and maintain |

|

Maximum laser power |

200W/300W |

|

Laser wavelength |

1064nm |

|

Maximum single pulse energy |

150J /200J |

|

Welding frequency |

≤30Hz |

|

Pulse width |

0.1-20ms |

|

The spot diameter adjustable range |

0.1-3.0mm |

|

The power consumption |

≤7KW/9KW |

|

Power demand |

AC220V+10%/50Hz/40A |

|

Control system |

MCU program control |

|

Cooling system |

Built-in water cooling |

1.Chinese and English systems can be switched quickly(We can install the language you need)

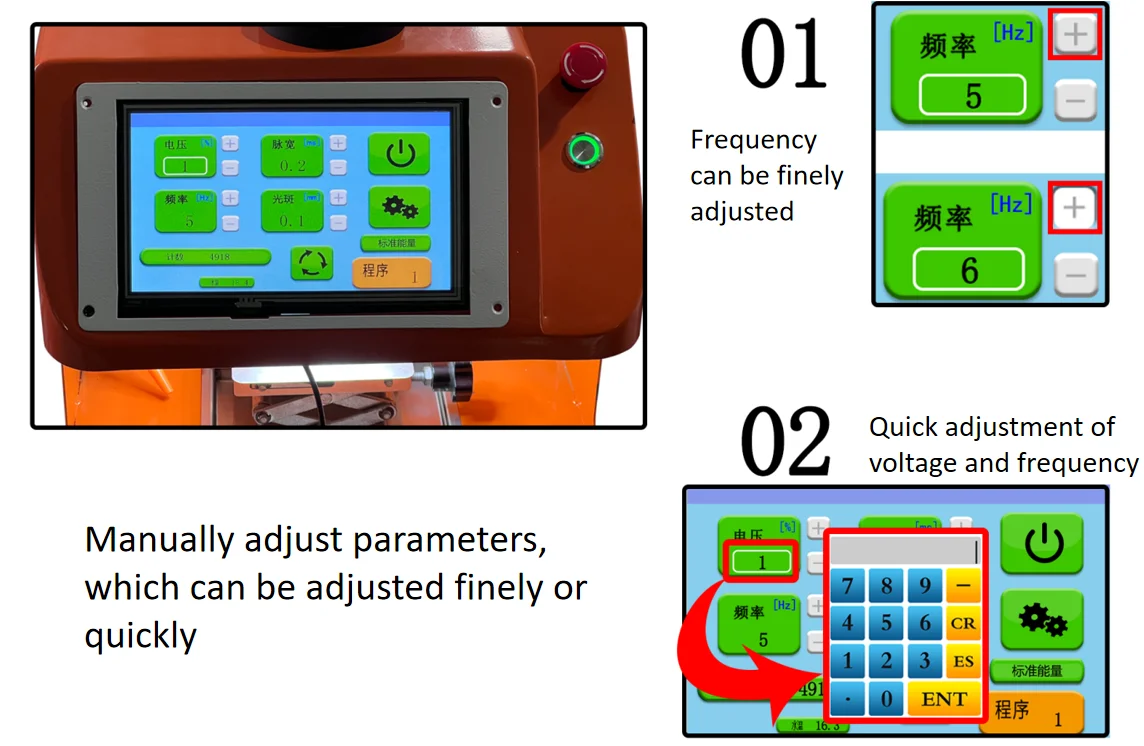

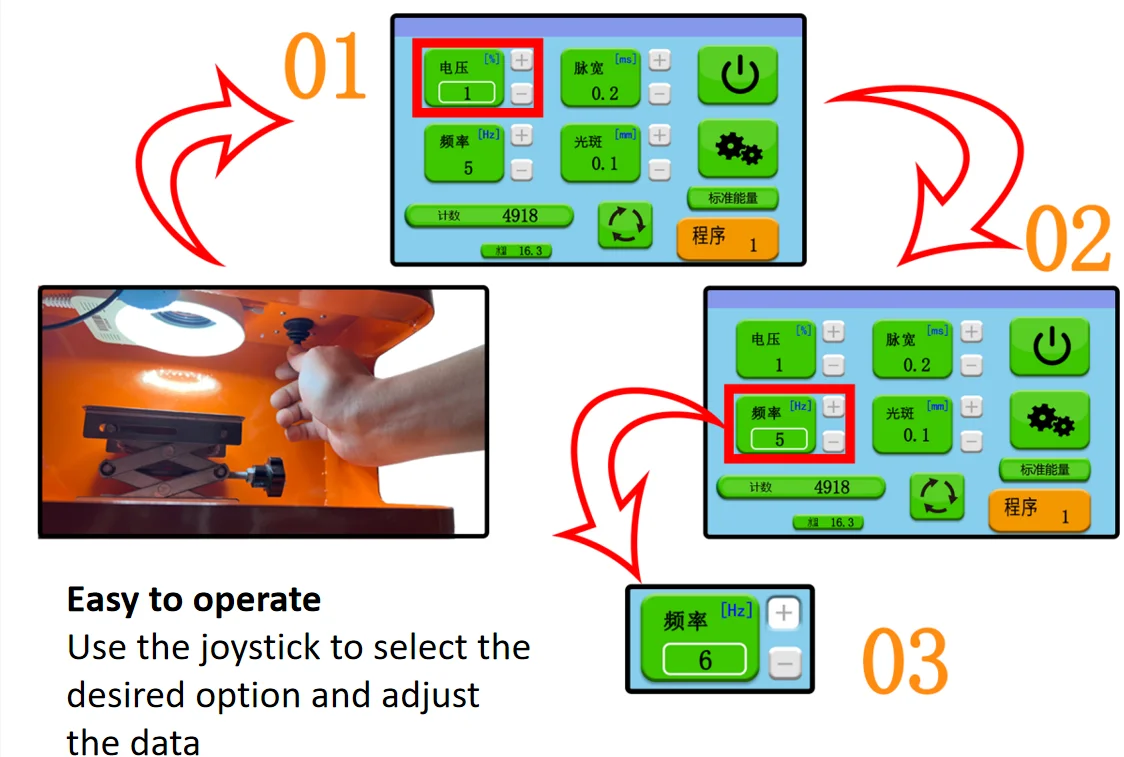

2.Manually adjust parameters, which can be adjusted finely or quickly

3.Easy to operate Use the joystick to select the desired option and adjust the data

Pre-sales services

*Inquiring and consulting support;

*Sample testing support;

*Visitting our factory;

After-sales services

*Engineers available to service machinery overseas;

*Training how to install and use the machine;

*Free parts;

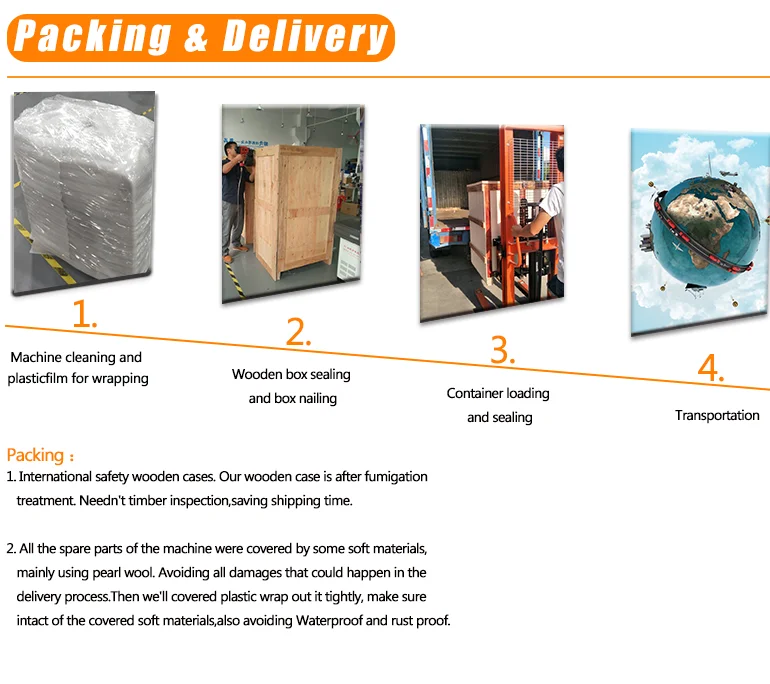

Packing :

Depends on different situation (weight, volume, country...), the shipping method could be different and its negotiable.

Payment:

Alibaba Assurance Order payment link; TT; LC; Western Union; Paypal

MoFang Laser (Shenzhen) Technology Co., Ltd. was established in 2013,providing comprehensive automation solutions for new energy, integrated circuits, brittle materials and other related fields. The company is headquartered in Shenzhen, In Italy, Germany, Malaysia, Thailand and other countries have after-sales technical team; there are more than 80 employees, 60% of them are R&D and technical staff.

Current main products:

Common laser marking / jewelry welding / metal and non-metal cutting machine

Large precision cutting machine/ PCB marking tracing production line

lithium battery Tab laser Cutting/cleaning machine,PACK production line.

SMT laser online tracking system.

Ultra-fast laser precision processing system.