×

×

From the manufacturing industry, automotive industry, aerospace and medical devices among others, CNC laser marking machines have become essential tools. The machines provide speed, precision and durability which makes them suitable for many types of materials in need of being marked or engraved.

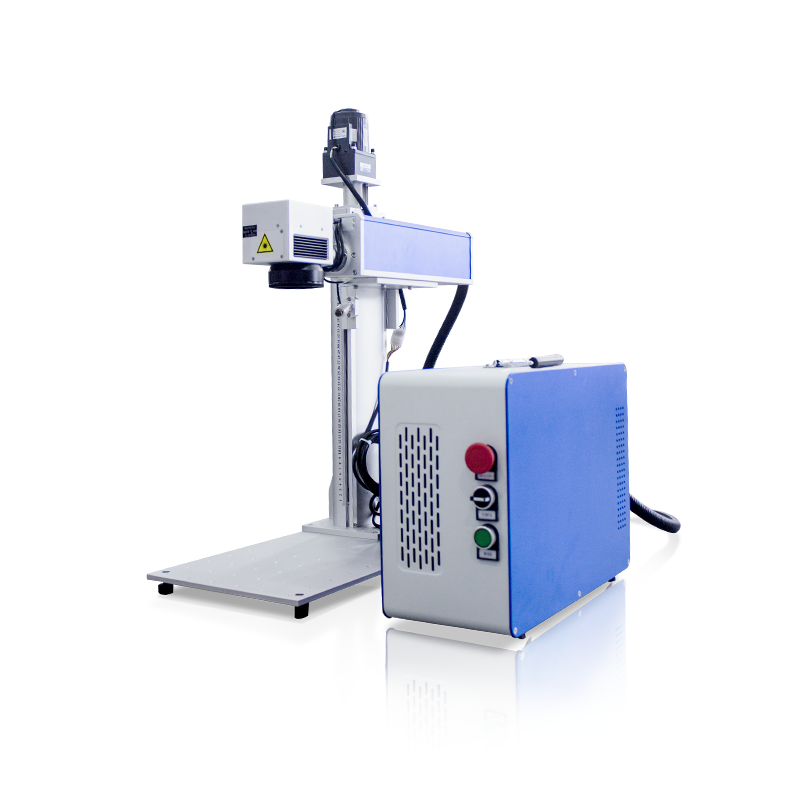

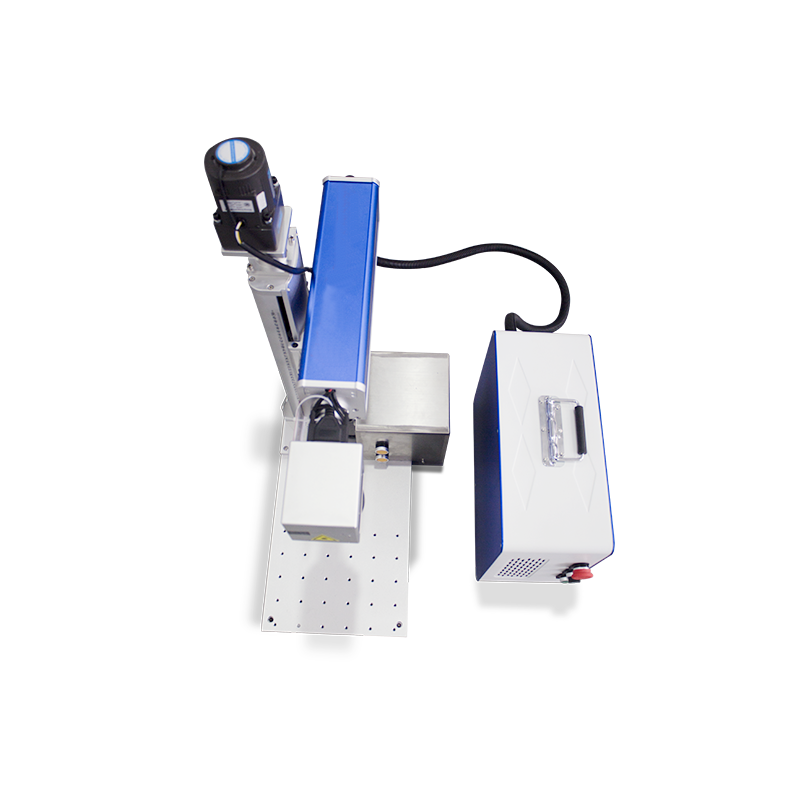

Design and Functionality

CNC laser marking machines are made to engrave diverse materials including metal, plastic or ceramic products. They similarly use a focused beam of light to create high-quality marks or engravings on the surface of these items. In addition to this, they are digitally controlled using Computer Numerical Control (CNC) systems that permit precise and repeatable marking to be realised.

Components of a CNC laser marking machine include the laser source itself, the beam delivery system, as well as the marking head. Ultimately it is carried out by beam delivery system which concentrates itself into an appropriate point from where all activities encompassing drawing are done. Optics that focus beam onto material under consideration are embedded in the latter.

Applications

There exists numerous applications for CNC laser marking machines throughout different industries. For instance serial numbers, part numbers and identification information can be applied in manufacturing sector. Vehicle Identification Numbers (VINs) and other crucial details on car parts can be marked in automotive industry using these systems. In aerospace industry this equipment is used to mark critical components with identity information and traceability codes. Last but not least medical device manufacturers apply these equipments to make essential information like lot number, expiration date etc recognized on devices.

Advantages

In comparison with conventional methods of labeling CNC laser markers boast numerous benefits over traditional labeling techniques since they offer better accuracy qualities during operation . It may undoubtedly produce scores if not thousands within an hour by computer numerical control (cnc), at times even millions thus making it suitable for the application of large volumes. Not to mention, these devices are long-lasting and require minimal maintenance resulting in less expensive solutions for producers who want to stamp their logos on a wide range of objects.

Having become an instrument that is very important in several industries due to its accuracy, speed and durability CNC laser marking machine has multiple uses. It can be used for various applications and materials from marking to engraving things. This is why many business enterprises have opted for CNC lasers as they improve their marking processes with numerous benefits associated with it.